Hydrogen production bipolar plates and fuel cells

Customised components.

Used in PEM, AWE and ALK electrolyers.

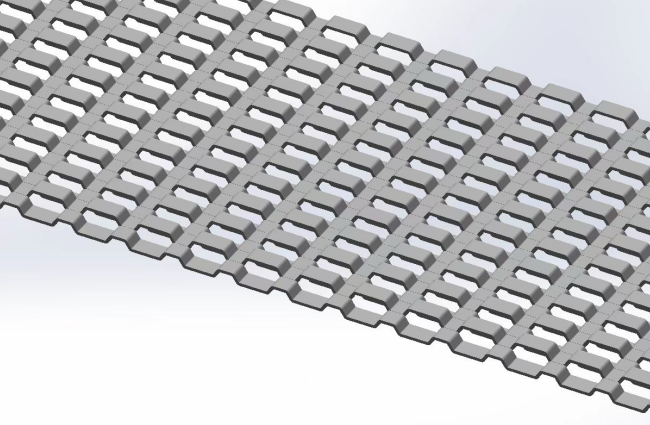

The membrane support grids are made of nickel-plated steel and pure nickel, and in different modes as 3Dstructure, flattened and corrugated. The products are characterized by smooth surface, uniform thickness, high electric densitylow resistance, corrosion resistance, uniform and smooth fow field, low maintenance cost and so on, so they are widely used inlarge electrolvzers, KiNSON can produce the products accordina to the reauirements of material. hole. thickness, strand. modeand dimensions.Our team is professional in the electrolyzer units and spare parts, including end load bearing plates, end polar plates, middlepolar plates, bipolar plates, besides welding and electroplating services. We have mature technology and successful projects.

Applications0.5-2000Nm³ Alkaline hydrogen electrolyzer.

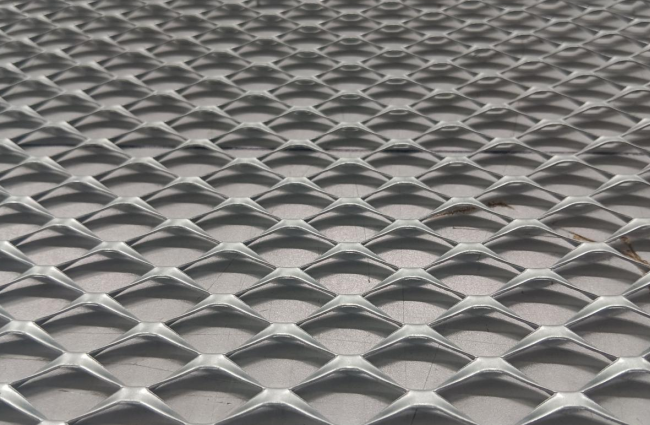

PEM Electrode Titanium Mesh

PEM electrode titanium mesh, thickness 0.04-2mm, width 100-1500mm, external dimensions, porosity, thickness, mesh can be customised. The product has the characteristics of low resistance, uniform current, no burr, not easy to fall off, flat and smooth. Compared with the electrode prepared by other materials, the cost is low, the life span is long, and the comprehensive performance is obviously improved, and it has been widely used in PEM hydrogen production industry.

The expanded titanium mesh, used as PEM electrode, has the range of the thickness 0.04-2mm, and the width 100-1500mm. The external dimensions, porosity, thickness, and mesh size can be customised. The product has the characteristics of low resistance, uniform current, no burr, no-easy falling off, and flat and smooth surface. Compared with electrodes prepared from other materials, electrodes with lower costs, longer lifespan, and significantly improved overall performance have been widelused in the PEM hydrogen production industry.

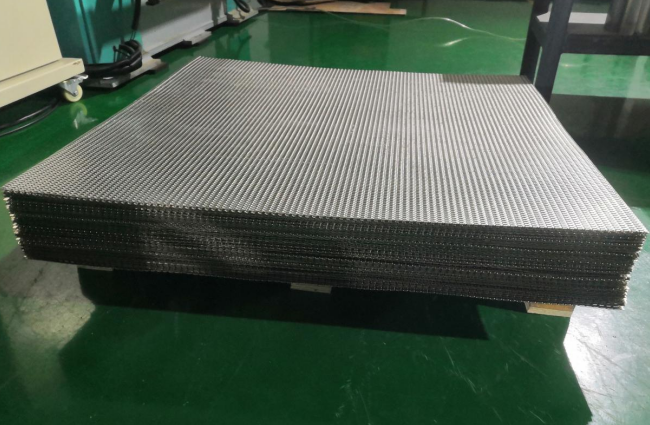

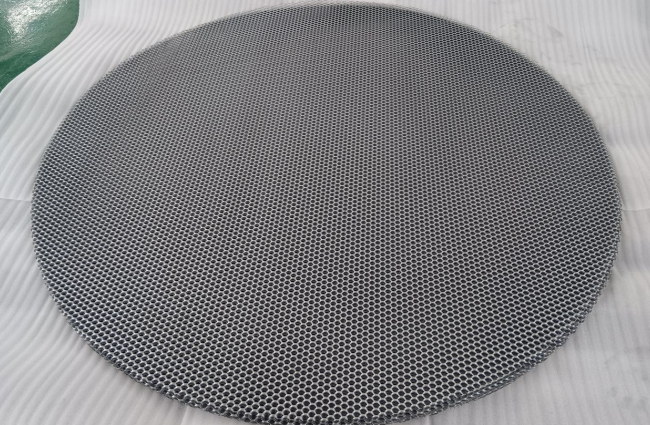

pre-electrode membrane support grid in alkaline water tank

We have special R&D equipments for hydrogen energy industry, and have successfully researched and developed many kinds of electrode mesh and support grid with many customers. The widest width of expanded carbon steel mesh can reach 2500mm, the widest width of expanded nickel mesh reaches 1300mm. Kinson is highly recognized by colleagues in the industry, and has established a good relationship of cooperation, with the deep processing capabilities of sandblasting, electroplating, chemical plating and other processes, rapid response, close cooperation, various material, many kinds of moulds, a wide range of categories, stable quality, and fast delivery.

|

Squre hole mesh

|

Squre hole mesh in production

|

Carbon steel- membrane support grid

|

Carbon steel- membrane support grid

|

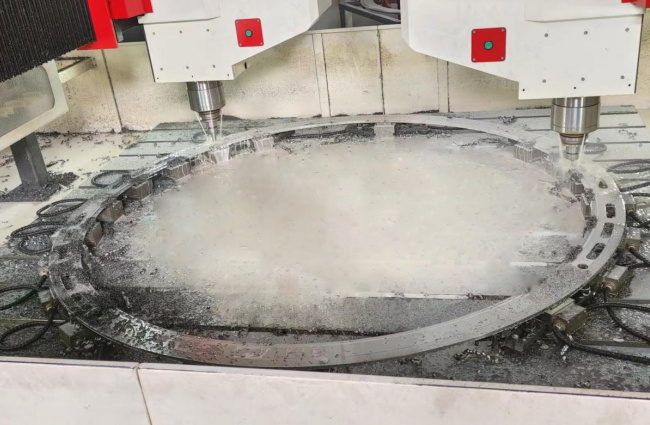

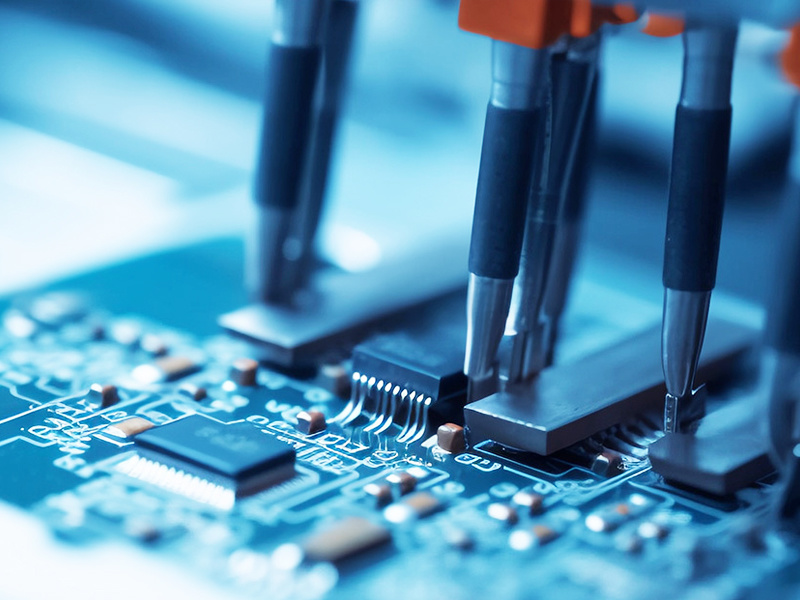

Bipolar plate automatic production line

The whole machine processing line is composed of 3 vertical lathes , 2 gantry milling machines , gantry robot and overturning platform and other equipment. It can realize unmanned handling work in the whole processing line, improve efficiency, and increase safety in the production process.

The welding platform comes complete with a correction platform, a welding platform and a weld-seam leveling platform,with automatic welding tracking system, automatic welding and leveling, which abounds the traditional spot welding and effectively improves weld quality.

Electroplating is all automatic, with the advantages as precise plating time control, slight error of coat thickness and stable quality.

|

On the vertical lathe

|

Grinding with Milling grind machine

|

Bipolar welding

|

Bipolar electroplating

|

More Applications

Get In Touch With Us!