Aerospace

Product Description

Generally speaking, metal aircraft made of aluminum can be used safely for decades, because the metal aircraft's own electrical conductivity is enough to protect the aircraft from lightning strikes, with the development of science and technology, composite materials are widely used in aviation aircraft, when lightning strikes or lightning current flows through the composite structure, it will cause this composite structure embrittlement, delamination or fracture. And the most serious damage to the composite structural parts is usually the highest energy density of the lightning inflow point or out point.

Usually, the flame or the plasma sprayed aluminum, the LSP metal mesh are used for lightning strik protection on composite structures. Due to the advantages of light weight, good flexibility, good combination on a compound curvature surface as well as excellent lightning protection effect, LSP mesh has become the main method of lightning current protection for carbon fiber composite structural components. The higher the conductivity of the outer surface of the aircraft, the faster the lightning current spreads, the smaller the energy concentration phenomenon, the smaller the damage, the lightning protection metal mesh provides a safe conductive path on the external structure, so that most of the lightning current is retained on the outside and quickly exported.

KINSON’s micromesh can effectively and directly defend against catastrophic structural damage from lightning strikes, dangerous electric shocks to passengers and loss of aircraft flight control, in addition to providing EMI shielding and Hirf protection against electromagnetic fields in space to prevent aircraft communications and electronic equipment.

Appliance

|

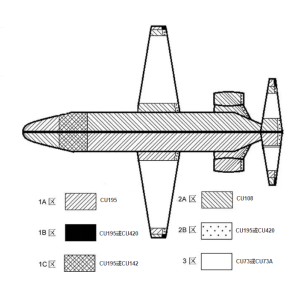

| Schematic diagram of three-level lightning protection zoning, metal mesh can be laid on the fuselage, wings, rudders, spoilers, vertical tail, ailerons, flaps, gap wings, and engine nacelles, etc. |

The advantages of KINSON’s LSP meshes are:

1, high conductivity; can withdraw the strike of 200,000 amperes and repeated lightning strikes;

2, excellent shielding, conductivity, heat transfer performance;

3, both lightning and EMI interference characteristics;

4, light weight and flexible, with good ductility and drape;

5, sigle in one uinit structure. Different from the woven mesh, the expanded materials do not lose strand and ensures uncompromised conductivity;

6, Uniformity of opening and thickness, making the surface smooth and the adhesive easier to penetrate;

7, flexibly designed with different weights and thicknesses according to different structures to meet the requirements of installation;

8, helpful to reduce the cost of material, installation and maintenance.

Product Parameters

| CU material for aerospace | ||||||

| KINSON Product Code | Cu73 | Cu73A | Cu107 | Cu141 | Cu195 | |

| Area weight g/㎡(±6%) | 73 | 73 | 107 | 141 | 195 | |

| LWD mm(±0.01mm) | 2.54 | 2.54 | 2.54 | 3.17 | 2.54 | |

| Thick l thickness mm(±0.005mm) | 0.050 | 0.100 | 0.060 | 0.076 | 0.076 | |

| Open areas %(±5%) | 80 | 80 | 75 | 80 | 65 | |

| Resistivity (mΩ) | LWD | ≤3.12 | ≤3.12 | ≤2.10 | ≤1.60 | ≤1.10 |

| SWD | ≤12.00 | ≤12.00 | ≤6.30 | ≤4.80 | ≤3.60 | |

| AL material for aerospace | |||

| KINSON Product Code | AL66 | AL78 | AL136 |

| Area weight g/㎡(±6%) | 66 | 78 | 136 |

| LWDl mm(±0.01mm) | 1.905 | 2.032 | 2.032 |

| Thick l thickness mm(±0.005mm) | 0.051 | 0.102 | 0.152 |

| Open areas %(±5%) | 52 | 52 | 60 |

More Applications

Get In Touch With Us!