Industrial

Expanded metals, along with our other metal alternatives, is manufactured with no waste and is available in 2D and 3D appearances. It has exceptional corrosion, heat, and impact resistance. The unique properties of lower and higher alloyed grades provide resistance to corrosion in many different environments. Moreover, 2D and 3D appeared can expand the area and carry much more catalysts. The manufacturing process adds rigidity to the original material and the mesh can be annealed to improve its formability. Expanded metal mesh is a versatile and durable one-piece construction that is used for a wide range of applications. Industries we commonly serve include HVAC services, filtration, petrochemical, food service, automotive, acoustics, architecture and more.

AutomotiveExpanded metals are perfect material of the speaker grill. Its one sigle unit structure is good looking and easy to make into speaker covers to protect the speakers. LSP on Automobile: The LSP mesh can be used for car body protection to prevent lightning damage to the car. |

|

|

FiltrationExpanded stainless steel mesh can be used for either primary filtration applications to protect critical downstream components or as internal cores to support the filtration media. Typically, expanded metals are used for these applications because they require strength and operate at higher pressures. |

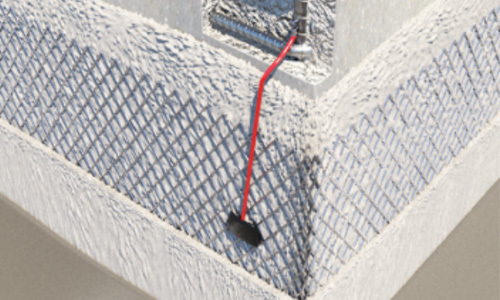

Cathode protectionSacrificial anode cathodic protection technology is based on the principle of electrochemical corrosion by connecting the protected metal (such as the steel structure of a bridge) with a more negative potential metal (sacrificial anode) and in the same electrolyte (such as seawater, soil, etc.). When the two metals are in the electrolyte, due to the potential difference, the current will flow from the sacrificial anode with a negative potential to the protected gold with a positive potential, making the protected metal become the cathode, thereby inhibiting or slowing down its corrosion. 1. One-time: The sacrificial anode cathodic protection system is a one-time anti-corrosion measure, because the anode material (such as zinc, aluminum, etc.) will gradually corrode and consume with the flow of current until it is completely exhausted. 2. No external power supply: Unlike other cathodic protection systems that require external current, sacrificial anode cathodic protection systems require no external power supply, reducing maintenance costs and complexity. 3. Effective protection: The sacrificial anode can provide continuous protection current and effectively prevent or slow down the corrosion process of the bridge structure. |

|

|

Cathode protectionBy utilizing the impressed current method, this supplementary anode arrangement delivers a protective current to the steel embedded within the concrete. Impressed current cathodic protection is a kind of technology widely used in building structure anticorrosion. It inhibits or slows down the corrosion process by applying an impressed current to the protected structure, which makes the surface of the structure become a cathode. |

More Applications

Get In Touch With Us!