Battery Extended Silver Mesh

Category:

Products

The expanded silver mesh is a metal mesh with excellent ductility, electrical conductivity and thermal conductivity, and is mainly made of pure silver or silver alloy.

features and advantages

Ductility: Ductile silver mesh has excellent ductility, which means it can be easily stretched, bent or shaped without breaking easily. This characteristic makes the expanded silver mesh very popular in applications requiring complex shapes or fine machining.

Conductive and thermally conductive: Silver is one of the best conductive and thermally conductive of all metals. Therefore, the expanded silver mesh is excellent in applications requiring high conductivity or high heat transfer performance, such as battery current collecting mesh, electrode mesh, etc.

Corrosion resistance: Silver has good corrosion resistance in most environments, which enables the expanded silver mesh to maintain stable performance in a variety of environments.

Aesthetics: Silver itself has a silvery white luster, making the extended silver net visually attractive, suitable for some occasions where aesthetics is required.

Description

The expanded silver mesh is a metal mesh with excellent ductility, electrical conductivity and thermal conductivity, and is mainly made of pure silver or silver alloy.

features and advantages

-

Ductility:

- Ducted silver mesh has excellent ductility, which means it can be easily stretched, bent or shaped without breaking easily. This characteristic makes the expanded silver mesh very popular in applications requiring complex shapes or fine machining.

-

conductivity and heat transfer:

- Silver is one of the most conductive and thermally conductive of all metals. Therefore, the expanded silver mesh is excellent in applications requiring high conductivity or high heat transfer performance, such as battery current collecting mesh, electrode mesh, etc.

-

Corrosion resistance:

- Silver has good corrosion resistance in most environments, which allows the expanded silver mesh to maintain stable performance in a variety of environments.

-

Aesthetic:

- The silver itself has a silvery white luster, which makes the extended silver mesh visually attractive and suitable for some occasions where aesthetics is required.

Application areas

-

Battery manufacturing:

- The expanded silver mesh is often used as a battery current collecting mesh, electrode mesh, etc., to improve the conductivity and stability of the battery.

-

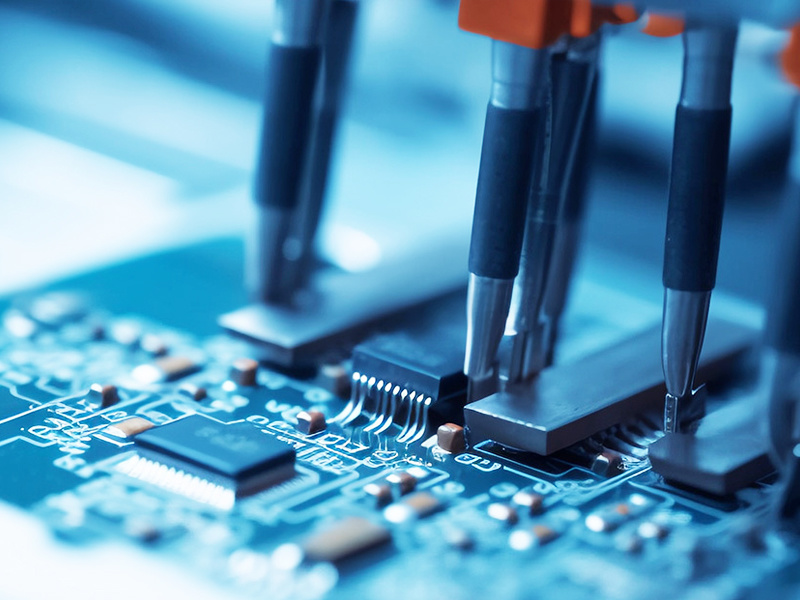

electronic industry:

- In the electronics industry, extended silver mesh can be used to make conductive parts of electronic components, such as conductive lines on circuit boards.

-

chemical field:

- Although silver has good corrosion resistance, expanded silver mesh has relatively few applications in the chemical industry, because other metals such as stainless steel and nickel may be more suitable in certain corrosive environments. However, in the chemical equipment that requires high conductivity, the extended silver mesh still has a certain application space.

-

Other areas:

- The extended silver mesh can also be used in precision filtration equipment, experimental materials and other fields to meet the needs of different industries.

More Applications

Get In Touch With Us!